Steel in industrial cleaning equipment: an efficient and eco-sustainable solution

In a world increasingly attentive to ecological and environmental issues, recycling is now part of the life of companies as well. We also see this trend in the cleaning sector of production processes: the steel alternative is preferable to plastic machinery. Let’s find out what are the characteristics and advantages of this material.

Table of contents

1. The importance of recycling also in cleaning

In modern society, the concept of recycling is finally entering the daily life of our families, creating a new culture and new habits. This renewed civic sense was not limited only to the family sphere: it has also affected the whole industry, first of all the food industry (leading to the creation of new low-impact packaging through the use of paper) up to the mechanical one, electrical, electronic, etc.

In short, this sensitivity has affected numerous sectors and the consequences are evident. Also in the area of internal cleaning of production processes. Companies are increasingly paying attention to purchasing a cleaning product (and its corresponding equipment) that is truly eco-friendly and that can be managed and disposed of at low costs.

From this aspect comes the precise philosophical choice of Geicos group. From the beginning we have embraced the use of steel for the construction of equipment to the detriment of the erroneously acclaimed plastic.

Plastic remains one of the most used materials in the world, but it has characteristics that are too harmful for environmental sustainability:

- Almost half of the plastic produced worldwide is destined to become waste in less than 3 years;

- 37% of plastic waste is not properly managed.

Steel represents a very valid alternative, let’s see why below.

2. Why precisely stainless steel?

It is 100% Recyclable

Believe it or not, steel can be recycled indefinitely without losing its original properties and is by far the most recycled material in the world. Steel from recycling does not degrade, not even in mechanical properties. Consequently, it is a material comparable to the “new”.

These features make it a perfect example of a circular economy. It is a model of production and consumption based on the principles of reuse, repair and recycling of products. The purpose? To ensure that they last longer and consequently reduce the number of waste produced and introduced into the environment as much as possible.

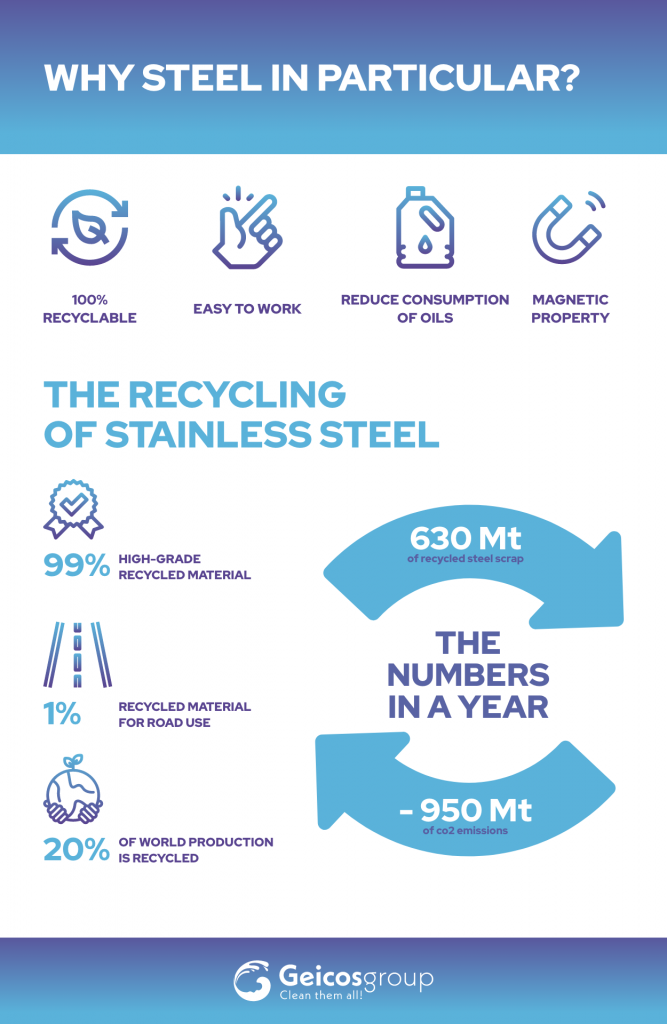

Let’s see some figures below to better understand the phenomenon of steel recycling (Ingenio):

- 99% of the recycled material for its production is first choice;

- Only 1% of the material, on the other hand, is used for road use;

- 20% of world steel production is obtained from the recycling of scrap.

It is easy to work with

Its high recyclability is also due to the fact that, unlike other materials, steel is easy to disassemble and separate. In some cases it can also be easily “crushed” reducing the spaces dedicated to it. Then, when the equipment has reached the end of its “career”, it will be taken to the appropriate recycling depots and then brought back to the foundry and regenerated.

This characteristic is defined with the term UP-Cycling, which identifies a process of using waste materials to create new objects of superior quality and value. In this way, by casting a steel structure, I will be able to produce a steel structure with the same mechanical properties.

There are several Down-Cycling materials (such as plastics), which are instead strongly subject to the loss of these properties and therefore must be used in lower level applications. So, in this case the material is transformed into an object that has less value than the original one.

It has magnetic properties

Another interesting aspect in steel recycling is its magnetic property, which facilitates its collection and separation at the end of its life.

Reduces oil consumption

We are also talking about consumption and pollution. In the first place, the recycling of steel drastically reduces the consumption of oil necessary for the production of materials from extracted raw materials. As a result, the heavy environmental burden caused by CO2 emissions and other polluting chemical elements is alleviated.

However, this is not possible with plastic, which involves a high use of fossil and chemical material in its creation (5% of the oil extracted is used for the production of plastic). Furthermore, even if recycled, it has a significant economic weight: the most widespread recycling method (the mechanical one) is extremely complicated, expensive and not very functional and cannot be applied to all types of plastics..

Let’s add one more detail: the surface of the plastics is hardly washable to perfection. Therefore it is often contaminated and this leads to invalidate or complicate the recycling processes themselves.

Another extremely important aspect that we often do not consider is the degradability of plastic: if inserted in a corrosive environment, it releases microparticles into the environment. A direct consequence is, for example, the pollution of the seas of which we are all witnesses.

3. The ultimate permanent material

For all this series of characteristics we can consider steel as the emblem and standard-bearer of Lavoisier’s first physical law, also known as the law of conservation of mass.:

“Nothing is created, nothing is destroyed, everything is transformed”

We therefore understand that steel is continuously transformed through its recycling processes, never actually being consumed. This process also leads him to perfectly describe the concept of “permanent material“, which is the basis of the aforementioned circular economy.

630 million tons of steel scrap are recycled every year, resulting in a saving of approximately 950 million tons of CO2 per year (Green Report, June 2020). In particular, according to the CONAI in 2019 Italy would have recycled 399 thousand tons of steel. In fact, Italy ranks first in the European Union for the energy efficiency of its steel processes (according the comunicato di Promozione Acciaio, the energy consumption of the Italian steel industry fell by 25% from 1995 to 2019). Also in Italy, the lack of raw material has led to the development of the cycle with electric furnace: over 78% of the production at national level derives from the remelting of ferrous scrap.

4. The quality choice made by Geicos group: only AISI 304 stainless steel

This explains the strategic and eco-friendly choice of Geicos Group, which only produces equipment in AISI 304 stainless steel. In this way we combine the reliability of the selected components with the guarantee of highly recyclable raw materials.

Our industrial parts washers are developed entirely with respect for the environment and the protection of the workers who use them. Our detergents are also ecological and their dispersion is reduced to a minimum.

Our idea of cleaning goes hand in hand with sustainable development, because we really want to make a difference.